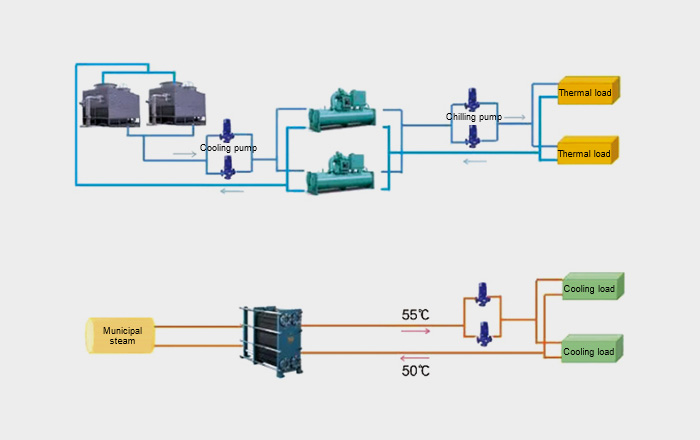

Pre-transformation System Chart

Take an electronics factory as an example. The water chilling unit before transformation is used as the cooling source. The municipal steam is used as the heating source. The heating and cooling system diagrams are shown below:

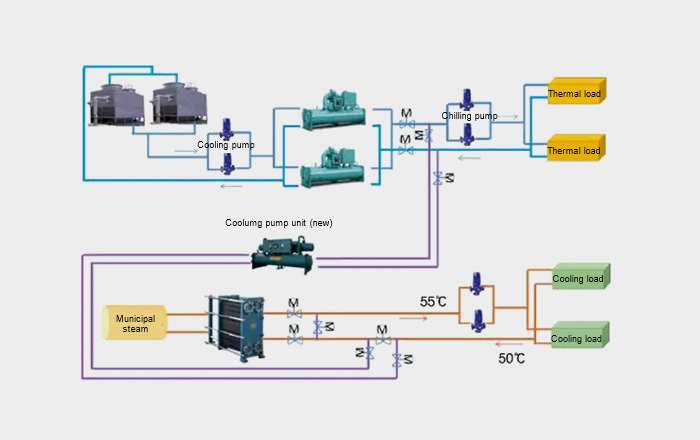

Post-transformation System Chart

York high-efficiency heat pump unit is used in the transformation scheme. One end supplies chilling water and the other end supplies hot water, so as to realize combined heating and cooling. This way, maximum overall energy efficiency of the system is achieved. Its schematic diagram is as follows: