The Johnson Controls combines advanced fresh air handling unit with heat recovery technologies.

Commonly used heat recovery technologies include:

Running Heat Recovery

Heat Pipe Heat Recovery

Liquid Circulation-type Heat Recovery

Running Heat Recovery

It is an integrated fresh air and exhaust air unit. The central part is a heat runner recovery unit. The runner functions as a heat storing core. The fresh air flows through a semicircle of the runner. The exhaust air flows through the other semicircle in a reversed way. The fresh air and exhaust air flow through the runner in a reversed way alternatively to realize heat exchange. In addition, the total-heat runner is used to ensure the moisture is separated from the air flow while heat is exchanged. The moisture flows into the moisture absorbing layer in the core for moisture exchange.

Heat recovery rate is as high as 70% to 80%;

It is of the compact design;

The heat carrier is made of the anti-corrosion aluminum. Surface coating is possible;

Total-heat exchange is possible;

Water and air can both be used for washing.

Heat Pipe Heat Recovery

Heat pipe is a heat exchange element that draws on phase change of working medium such as ammonia for heat exchange. When one end (evaporation section) of the heat pipe is being heated, the working medium in the pipe is vaporized due to the heat. The gaseous working medium, after heat absorption, flows to the other end along the pipe (condensation section), where the heat is released to the heated medium. The gaseous working medium becomes liquid due to heat loss and condensation, and flows back to the evaporation section downwards due to capillary and gravity. A thermodynamic cycle is thus completed.

It has a compact design. The heat transfer area of a single volume is remarkable.

It functions reliably and safely and has a long service life.

Each heat pipe forms a heat exchange system, and can be replaced easily.

There will be no cross contamination between fresh air and exhaust air.

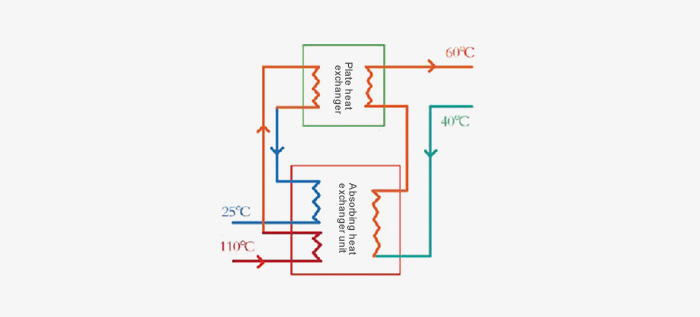

Liquid Circulation-type Heat Recovery

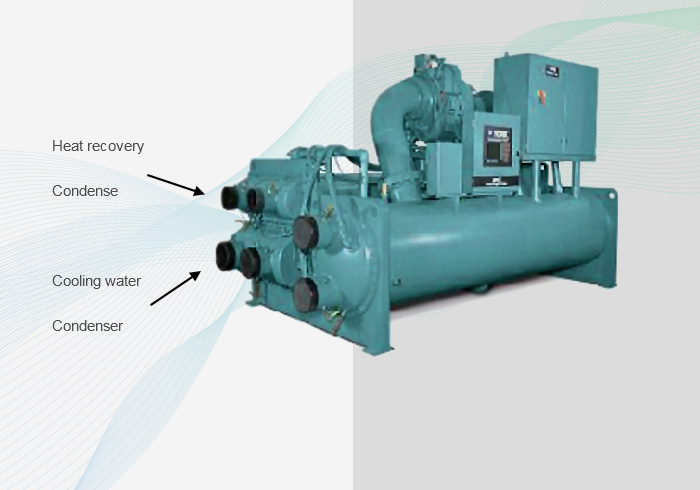

Liquid circulation-type heat recovery is also called intermediate thermal-coal heat recoverer or mixed-type heat recoverer. It is a system made up of two sets of “water-air” heat exchanger (air cooler/heater) installed within the exhaust pipe and fresh air pipe connected through pipes. In order to ensure constant circulation and flow of liquid in the pipe, a circulating water pump is installed in the pipeline.

There will be no cross contamination between fresh air and exhaust air.

The heated side and heating side is connected by a pipe. There is no requirement for location. It is of compact design and flexible arrangement.

Both the heat exchange and circulating water pump can be ordinary general products.

It has a long service life and low operation cost.