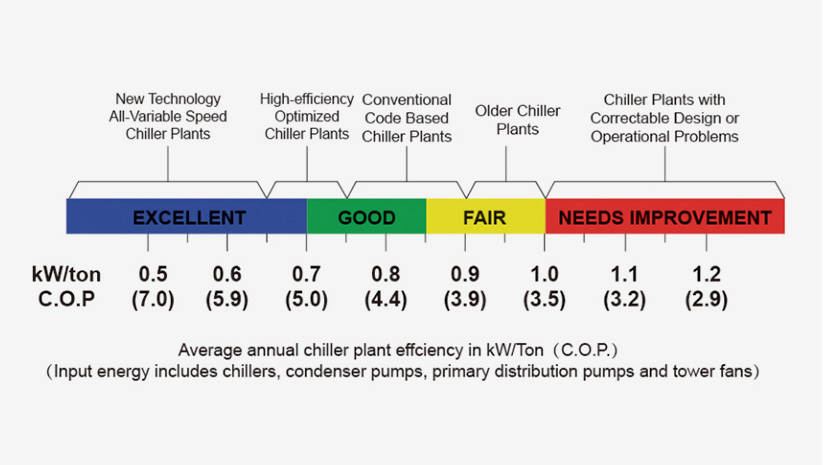

The high-efficiency machine room service of Johnson Controls is a kind of service that involves energy-conserving transformation of energy-audited chiller plant and guarantee of the after-transformation efficiency of the chiller plant. To obtain a high energy efficiency chiller plant, in-depth optimal design of the systematicness, intelligence and integration of equipment in the central A/C plant room, including water chilling unit, chilled water pump, cooling water pump, cooling tower, pipe valves and control system, is needed, so as to ensure the entire chiller plant sustains its maximum range of overall efficiency throughout the process. It is a complete solution, and an effective tool developed by Johnson Controls based on its more-than-100-year innovation experience in HVAC and building automatic control, through constant integration and in-depth exploration. It aims to improve the overall performance of the chiller plant and lower the operation cost. Johnson Controls will provide effective confirmation of the actual level of the overall energy efficiency of the chiller plant.。

Seven Steps to Build A High-efficiency Machine Room